mastermix gear drive compact

Article number 2381-0000-1000

Weight 640.0 kg

System type 2K gear dosing system

Material containers 600 ml foil bag and 20 l hobbock

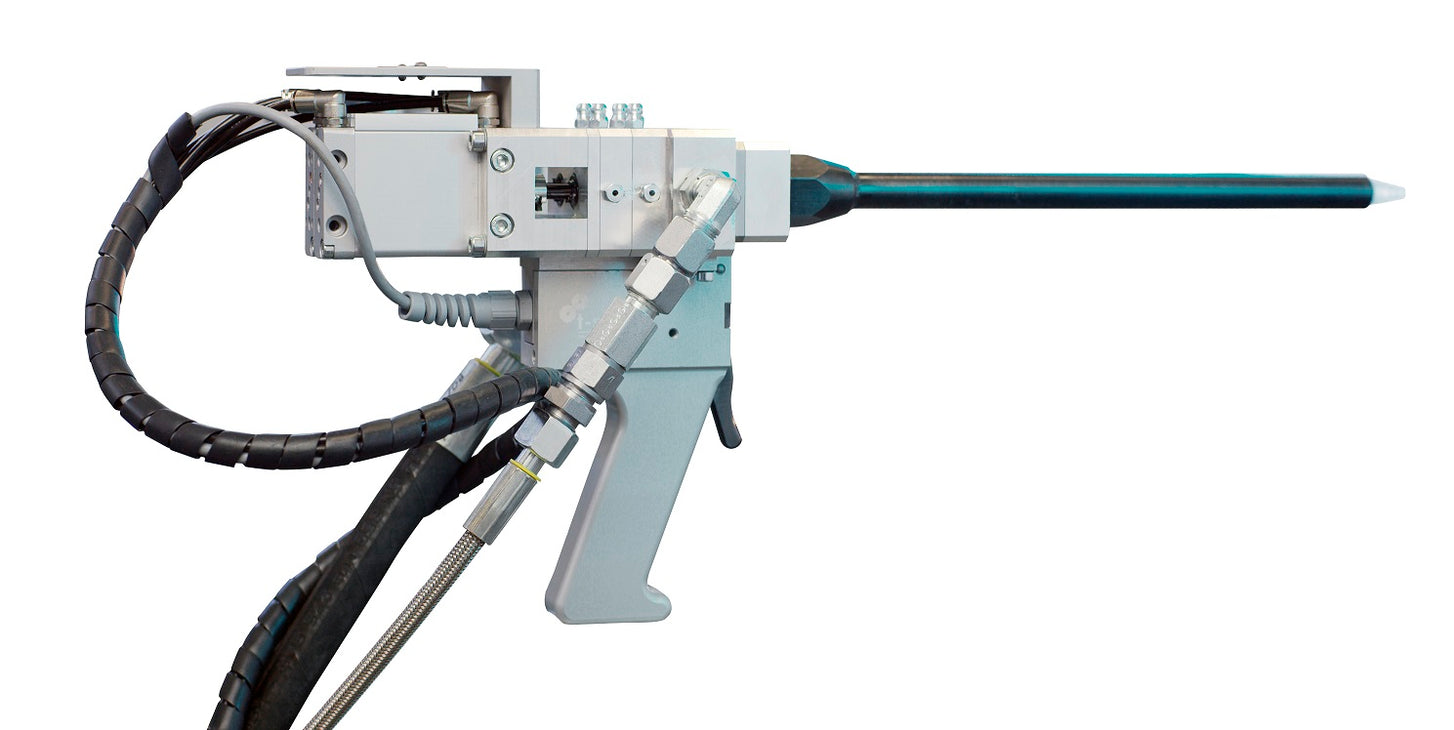

Application Manual or automated application of adhesives and sealants

Documents

Flexible & modular

For manual applications or automated processes with robots or portals

Precise & consistent

Exact mixing ratios thanks to gear pumps with even material flow

Low maintenance & open

Open, accessible design with easy maintenance and no unnecessary panels

Durable & proven

High-quality Siemens and Festo components for long-term industrial use

Technical data

- Output depends on material viscosity, temperature, material batch, etc.

- Pneumatic control of A-side

- B-side control pneumatic

- Power connection 3 x 400 V+N+PE/ 3.8 kW

- Compressed air requirement 6 bar, 600 l/min

- Dimensions L x W x H 1500 x 1000 x 1800 mm

- Height with swivel arm 2500 mm

- Standard swivel arm length 1200 mm

- Standard hose length 2500 mm

- Weight approx. 640 kg

Standard equipment*

- Siemens S7-1500 / Touch Panel / Ethernet-capable for later integration into automated systems

- Software interface prepared for controlling the automation (standard via Profinet; other interfaces on request)

- Siemens servo motors

- Digital pressure sensors

- Dead volume-free design

- Optical and acoustic pot life monitoring

- Signal light for system notifications on the display

- Material shortage monitoring

- Overpressure protection

- Follower plate with reduced residual quantity

- Two-hand safety control for A and B sides

- Drum empty signal with pump shutdown

- Maintenance-free pump sealing

- Variable adjustable mixing ratio

- Optimized 200l drum change (recesses in base plate for pallet truck)

*Equipment may vary depending on project requirements

Special equipment

- Other container sizes on request

- Follower plate heating A and B components

- Cartridge filling (1K and 2K)

- Parking position with automatic blind shot

- Permanent control of the mixing ratio by volume measuring cells

- Extension working hose

- Special paint finish on request

- Swivel arm extension

- Swivel arm extension

- Mobile system with wheels

- For further options see brochure "Optional for mastermix series" or on request.

Frequently Asked Questions (FAQ)

Our services at a glance

Maintenance contract

Plannable costs thanks to regular inspections with documented statuses. Price advantages for labor and spare parts, tailored to operating time and usage. Plannable.

Spare parts service

Over 3,500 items in stock, fast shipping, and assistance in identifying required parts. We shorten downtimes, ensure workflows remain reliable, and processes remain stable.

Remote support

Permanently free of charge: Support via video call, WhatsApp video, phone, or email. Remote analysis and solutions are available promptly on weekdays and clearly documented.

Maintenance & Repair

Preventive maintenance and prompt repairs, on-site or in our workshop. Transparently documented for high plant availability, safety, and process stability.

Training

Practice-oriented training courses provide operators, maintenance staff, and technicians with the know-how to operate systems safely and efficiently. We tailor the content, duration, and format precisely to your processes – either at your site or at our facility, offering clear, hands-on practical experience.

Workshop service

In our workshop, we repair components, assemblies, and complete systems that are sent to you. Upon receipt, we inspect the damage and provide a detailed cost estimate. Once you approve the repair, our specialists will carry out the repair, test its functionality, and promptly return the device to you.