Technology Philosophy

Thoughtfully Designed. Modular. Future-Proof.

- Developed and manufactured in Germany.

- Siemens and Festo components.

- Open, service-friendly design without unnecessary covers.

- Modular platform, quickly adaptable and expandable.

- Built for continuous industrial use: robust, durable, process-safe.

- Automation-ready: prepared for robot and gantry integration (PROFINET).

- Custom configuration instead of standard.

Our commitment: technology that connects – in daily operation and in collaboration.

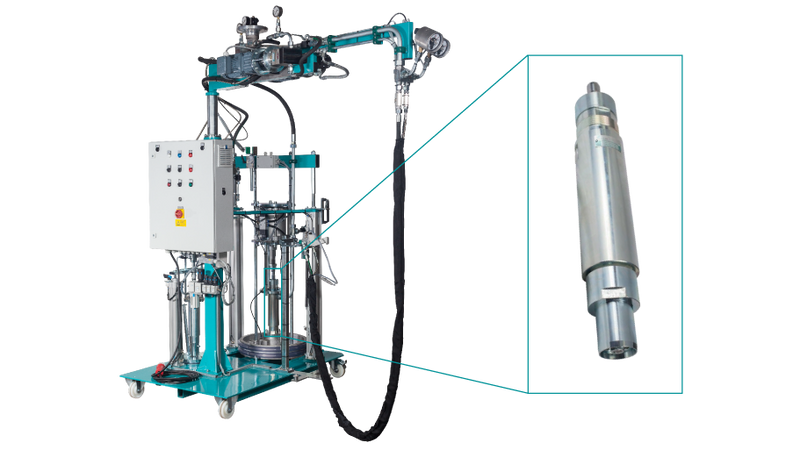

Piston Pumps

Powerful Delivery from Original Containers

Our ram pumps transfer pasty or highly viscous materials directly from the container – with pressures of up to 360 bar. Even extremely thick media are dispensed reliably. The robust technology is also suitable for low-viscosity components and ensures maximum process reliability with minimal maintenance effort.

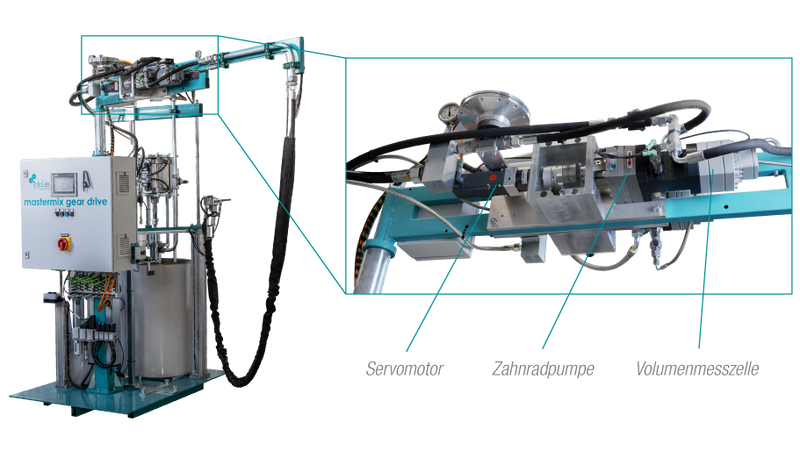

Gear Pumps

Precise, Continuous Material Dispensing

Gear pumps enable accurate, volume-based dispensing – especially important for 2C systems. They deliver material with low pulsation and consistent flow, even when processing low-viscosity or abrasive media. Ideal for applications with tight tolerances and high process responsibility in adhesive environments.

Progressive cavity pumps

Low Wear When Handling Abrasive Media

For highly filled or abrasive adhesives, eccentric screw pumps are the first choice. They provide nearly pulsation-free and very gentle material delivery. The flow rate can be precisely controlled via the rotational speed – ensuring long-lasting, low-maintenance systems with consistent dosing performance.

Flow Sensors

Real-Time Monitoring for Maximum Dosing Accuracy

Our sensors measure the volumetric flow directly in the material stream – in real time. They ensure the correct mixing ratio in 2C applications and monitor the dispensing quantity in 1C materials. This allows each application to be documented and ensures long-term reproducibility of the bonding process.

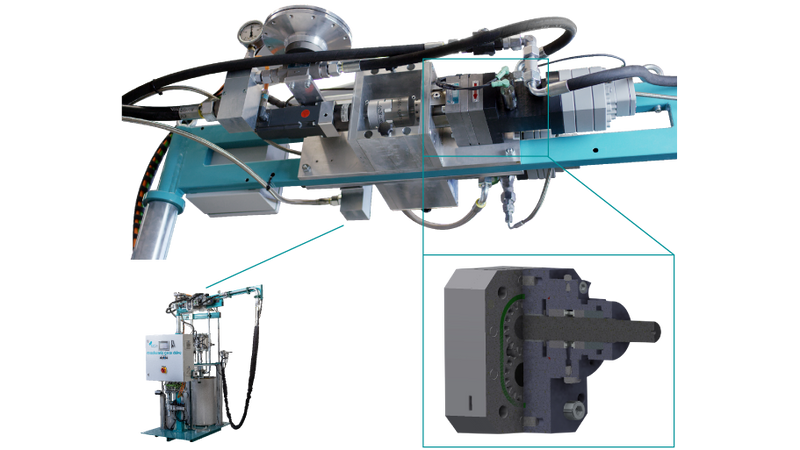

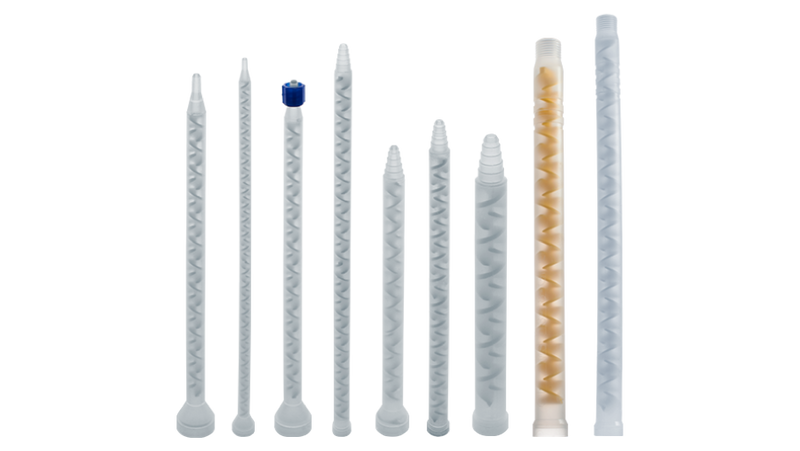

Mixing Technology

Static or Dynamic – for Perfect Results

The right solution for every 2C application: static mixers as a cost-effective disposable option, or dynamic mixers with rotating elements for maximum mixing quality. Both systems deliver homogeneous, bubble-free results – tailored to your material and process requirements.

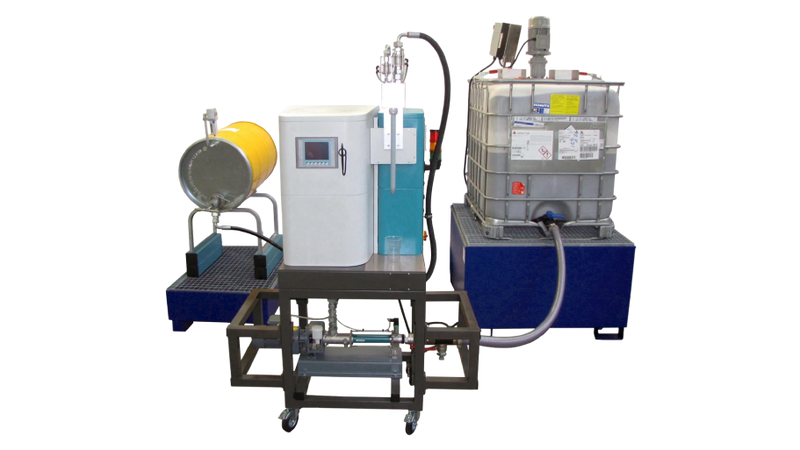

Booster Technology

Accelerated Curing of 1C Adhesives

Booster technology significantly reduces curing time in a controlled way. An additive is mixed in during dispensing and noticeably shortens the reaction time – independently of environmental conditions. This increases cycle speed and reduces downtime in production.